Best Practices for Effective Conveyor Belt Rip Repair

Belts tear every day. The reasons behind why are numerous. Other belt conveyor components like rollers can slice right through a belt when worn. A mistracking belt running into a structure can wear a belt so much it can tear. Even a jagged piece of the material you are conveying can produce a major or minor tear in your belt.

In my 25 years at Flexco, I have traveled from site to site testing products and training operators on best practices for belt conveyor maintenance. And I have seen a lot of things cripple a site – but there is none worse than a nasty, jagged lengthwise rip, especially when a service crew isn’t available to come fix it (because of something as odd as a global pandemic) or when the money just isn’t in the budget to bring a crew in to get it done.

So I will tell you what I tell everyone when I’m on site and this happens … you don’t need a service crew to get your belt up and running. You just need to grab your PPE, some rip repair fasteners suited for the type of belt you’ll be fixing, and a few of the tools used to install the fasteners.

Why Bolt Solid Plate Fasteners?

Now before I get specific about rips and how to fix them, I want to address which fasteners are best for rip repair. While there are a lot of different kinds out there, we find that Bolt Solid Plate Fasteners are the ideal fasteners for quick and easy belt repairs. The top-and-bottom plate compression and high-tensile-strength bolts ensure that your belt will be held together under the toughest of circumstances. Flexco® Bolt Solid Plate Fasteners have specially-formed teeth that penetrate the carcass and piloted bolts for quick and easy installation. You can also choose between hand and power installation, and install them from the top or bottom of the belt, which is important because rips never occur in convenient places.

Now before I get specific about rips and how to fix them, I want to address which fasteners are best for rip repair. While there are a lot of different kinds out there, we find that Bolt Solid Plate Fasteners are the ideal fasteners for quick and easy belt repairs. The top-and-bottom plate compression and high-tensile-strength bolts ensure that your belt will be held together under the toughest of circumstances. Flexco® Bolt Solid Plate Fasteners have specially-formed teeth that penetrate the carcass and piloted bolts for quick and easy installation. You can also choose between hand and power installation, and install them from the top or bottom of the belt, which is important because rips never occur in convenient places.

Choose your rip

Now let’s take a look at some common rips that can be fixed quickly and easily to get your belt up and running again.

Small puncture - A small puncture can be healed by applying a standard Flexco Bolt Solid Fastener crosswise on the belt. Pro Tip: No. 2 1/14 fasteners should be used to repair steel cable belts.

Clean, lengthwise rips and edge tears - Standard Flexco Bolt Solid Fasteners can be applied to the length of the rip over the damaged area.

|

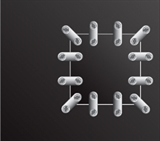

| Standard Bolt Solid Plate Fasteners can be used for small punctures, lengthwise rips, and edge tears, taking care to space them in accordance with what materials you are using. |

Jagged, lengthwise tears and soft spots - Bridging soft spots is a good preventative measure to avoid belt damage. When bridging a soft spot or repairing a jagged tear, use the same method, integrating standard Bolt Solid Plate fasteners with three-bolt rip repair fasteners.

|

| Note the placement of the three-bolt fasteners on the rip line. Two of the three bolts should be placed along the week or “flap” side of a jagged tear to increase stability. |

Pro Tip: Rip repair is actually quicker and easier than installing a splice in your belt.

Check out this great video that walks you through all the steps!

Large holes - For larger holes or punctures, a patch of belting can be attached to the original belt using standard Bolt Solid Plate Fasteners. Make a square hole in the belt, cutting out the damaged area. You can now use that damaged piece to cut a patch from the new belting.

|

| Flexco recommends first securing the patch on the corners and then adding the fasteners on the side. |

When time is of the essence - If you don’t have time to take out your power tools and you need a temporary fix, Flexco recommends the Turtle #16 drive-on fastener. Space each fastener from four to size inches apart for best results until you can get a more permanent solution.

|

| Turtle fasteners work on belts from 3/8" to 9/16" thick needing temporary repairs. |

But wait, there’s more!

Because we can’t fit all this great knowledge into only one blog, we invite you to keep an eye out for our next one – The Do’s and Don’ts of Rip Repair – written by Senior Product Manager Aaron Rosso, which will provide you with more great tips and best practices for rip repair. Sign up to have our newest blogs delivered to your inbox the moment they are published so you don’t miss this great information.

For more information on Flexco Rip Repair Fasteners, click here.

Authored by: Russ Heintz, Training and Technical Specialist

Russ Heintz has been with Flexco since 1995, working in various roles within the company before becoming Training and Technical Specialist. In this role, Heintz focuses on the efficiency of our products through in-house and field testing. Heintz also regularly conducts classroom and hands-on, internal or on-site training with Flexco employees, distributors, and customers.

Subscribe to the Flexco Blog

Related Blogs

Published Date

June 17, 2020Product Group

- Mechanical Belt Fastening Systems

Issues

- Belt Damage

- Belt Wear

- Downtime

- Maintenance