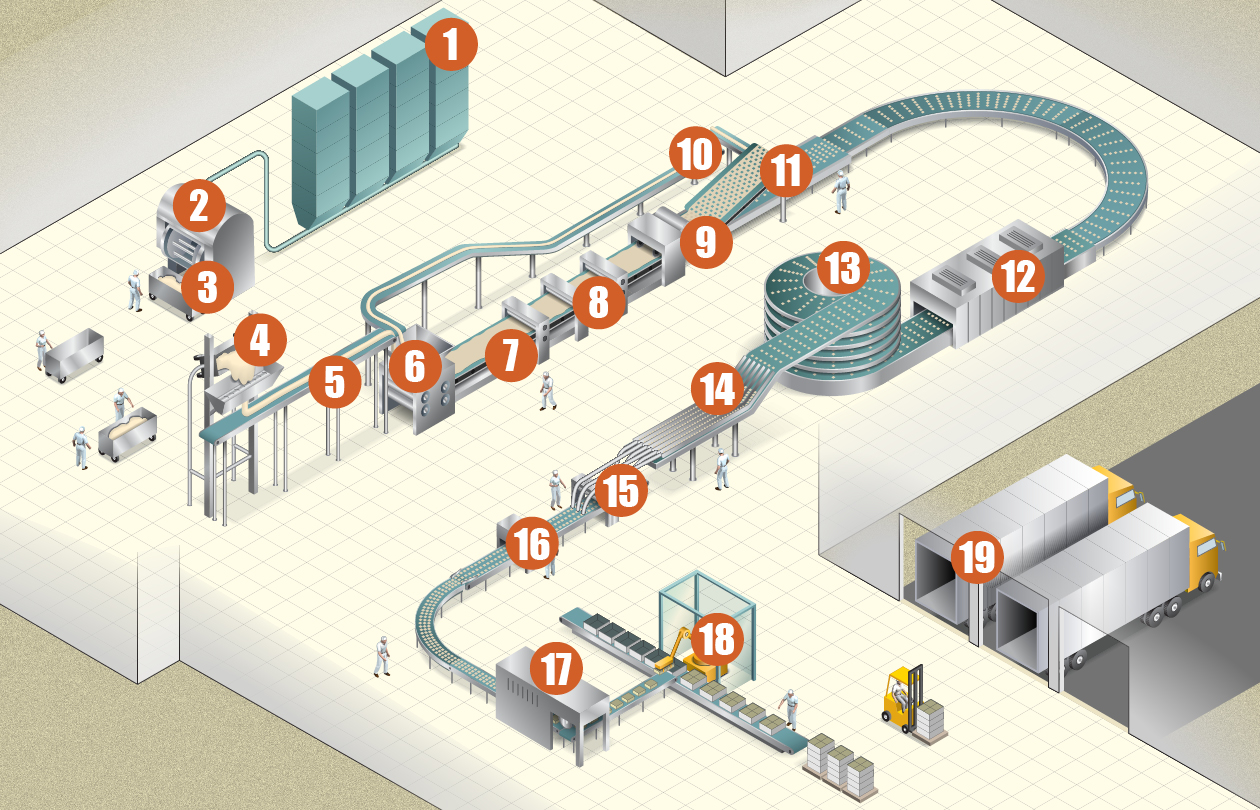

1. Dry and Wet Ingredient storage

Dry and wet ingredients are stored in a contained area or room to keep dust confined to that area. The silos deliver the dry ingredients directly to the mixers via a piped system that utilizes vacuum or air pressure to transport the ingredients directly to the mixers. Oil, water, and other liquid ingredients are piped directly into the mixers via a series of computer-regulated pumps. The amount of each liquid is carefully controlled per the needs of each specific recipe.

2. Mixing

The mixing of ingredients sets the chemical process side of baking in motion. Industrial mixers can be horizontal or vertical stand style mixers. Large industrial mixers are capable of mixing 1,000 lb. (450 kg) to 2,000 lb. (900 kg) of dough. Secondary ingredients such as rye seeds and rye flour are often added to the mixer manually.

3. Rough Trough (shown) and dough hopper

In some industrial baking dough processing, mixers empty the dough into large troughs. The troughs are then transported by hand or by guided robotic transport over to a trough elevator.

Some dough hoppers in cookie and cracker dough incorporate a cutting operation. Because the dough with most cookie and cracker recipes is so thick and heavy, it cannot be pumped out of the hopper. Instead, the dough is transferred out of the hopper in slices or slabs. The chunks are often cut with a guillotine-style cutter. The dough is transported to the end of the hopper via an internal conveyor belt located at the bottom of the hopper that may be referred to as a “belly conveyor” or “belly belt.” The dough in the hopper is conveyed into the guillotine cutting knife incorporated into one end of the hopper to be cut to a roughly-set dimension. The conveyor pulls the dough from the bottom of the dough lump. The internal conveyor in some hoppers contains dual drives. This is required due to the weight of the dough, which can be up to 2,000 lbs (900kg).

ISSUES

- Endless Splice Failure

- Dough carryback

- Belt mistracking

SOLUTIONS

High quality splices made quickly are key in industrial baking operations. The Novitool® Aero® Splice Press is the best and fastest endless splicing press available. There can be up to 2500 lbs. of dough in the hopper when full. Live-bottom dough hoppers require a strong endless splice free of pin holes.

The Novitool® Pun M™ Mobile Finger Punch can be used at the conveyor site and does not require electrical power. This can speed up the processing time of the splice, thus reducing conveyor downtime.

The FGP Food Grade Precleaner can be installed on the return side of the belt at the first bend pulley, past the nose bar to tackle carryback. Removing the potential carryback dough promotes better overall belt tracking reducing one of the larger pain points.

A squarely-cut belt end is very important to achieving a perfect finger splice that tracks well. The Laser Belt Square offers a quick and accurate way to locate a perfect belt cut reference line, every time.

The 845LD Belt Cutter offers a quick, safe, and accurate way to make a perfectly straight cut belt in a single pass. A straight cut is important in achieving a finger punch that is square to the belt edges.

4. Dough trough Elevator

The trough elevator lifts the trough and gently dumps the dough onto a receiving dough transport conveyor. Trough elevators are also used to add special ingredients, such as chocolate ships, into an industrial mixer 1/2 way through the cookie dough mixing process.

5. Dough Transport/Divider feed belt

Dough transport and divider feed conveyors are used to transport dough to pre-sheeters and dividers, or other dough transport conveyors.

ISSUES

- Dough sticks to belt

- Plied belt endless splice failure

- Monolithic belt splice failure

- Belt mistracking

SOLUTIONS

Carryback and dough release is a common problem with dough trasnport conveyors. Installing an FGP Food Grade Precleaner on the belt can reduce carryback and provide production gains as the scraped dough will drop into the dough sheeter or dough divider.

Quick and efficient, the Novitool® Aero® Splice Press offers superior finished splice quality in the quickest time possible. The quality of the finished splice helps to ensure long splice life with dough transport belts that utilize traditional plied belting. Downtime can be a significant cost to industrial baking operations. Every minute saved during a splicing operation can equate to hundreds of dollars of production output gained.

The Novitool® Pun M™ Mobile Finger Punch can be used at the conveyor site and does not require electrical power. This can speed up the processing time of the splice, thus reducing conveyor downtime.

The Novitool® Amigo™ Splice Press is quick, accurate, and safe, offering a superior butt splice. The “no touch” aspect of the heating element means that monolithic belts utilizing longitudinal cords can be spliced with little worry of cord material poking through the top or bottom surfaces of the belt.

Alligator® Spiral Lace offers the lowest profile mechanical splice option. And it is a completely non-metallic fastener. A great solution for premade replacement belts offering a hinged splice that is quick to install, keeping critical downtime to a minimum. Available in both food grade white and food grade blue options, it is a great option for all industrial baking facilities.

All great splices begin with a perfectly squared belt end. The Laser Belt Square offers a quick and accurate way to locate a perfect belt cut reference line, every time.

The 845LD Belt Cutter is a quick, safe, and accurate way to make a perfect cut in a single pass.

6. dough sheeter/divider

In cracker processing the mixed dough is conveyed into the pre-sheeter where the dough will be shaped to the initial processing gauge. For flaky crackers the pre-sheeter may have an integrated dough lamination process which layers dough sheets to create the flaky finished texture.

ISSUES

- Dough sticks to belt

- Product carryback produces tracking issues

- Finger splice failure

- Monolithic belt splice failure

SOLUTIONS

The FGP Food Grade Precleaner can be installed against the first bend pulley after the nose roller/bar on the return side of the belt. This will remove excess dough that sticks to the belt and will deposit it into a tray or onto a scrap take-away conveyor.

High quality, long lasting splices are key for dough gauging, which is why the Novitool® Aero® Splice Press is perfect for the job. Popped fingers can catch on the dough, causing the dough to tear, as well as creating a potential contamination issue. And splicing speed is always important in industrial baking operations.

The Novitool® Pun M™ Mobile Finger Punch can be used at the conveyor site and does not require electrical power. This can speed up the processing time of the splice, thus reducing conveyor downtime.

The Alligator® Spiral Lace Fastening System offers the lowest profile mechanical splice option and is a completely non-metallic fastener. It is also a great solution for pre-made replacement belts offering a hinged splice that is quick to install, keeping critical downtime to a minimum. Available in both food grade white and food grade blue options, it is a great option for all industrial baking facilities. Ideal for most industrial baking applications, including metal detection belts.

The Novitool® Amigo™ Splice Press creates a consistent butt splice with no air bubbles or imperfections. The pre-heat option makes it possible to create a great splice in even the most humid of environments. And the actual splicing process is fast and efficient, allowing for the lamination belts to be up and running as quickly as possible.

All great splices begin with a perfectly squared belt end. The Laser Belt Square offers a quick and accurate way to locate a perfect belt cut reference line, every time. A squarely-cut belt end is very important to achieving a perfect finger splice that tracks well.

The 845LD Belt Cutter offers a quick, safe, and accurate way to make a perfectly straight cut in a single pass. A straight cut is important in achieving a finger punch that is square to the belt edges.

7. take off conveyors - gauging rollers and sheeters

Each of the sheeter and gauging roller positions will have an associated take-off conveyor. The conveyors vary in length but are generally 10ft (3m) or less in length.

ISSUES

- Dough sticks to belt

- Belt tracking issues caused by carryback

- Finger splice failure

SOLUTIONS

The FGP Food Grade Precleaner can be installed against the first bend pulley after the nose roller/bar on the return side of the belt. This will remove excess dough that sticks to the belt and will deposit it into a tray or onto a scrap take-away conveyor.

High quality, long lasting splices are key for dough gauging, which is why the Novitool® Aero® Splice Press is perfect for the job. Popped fingers can catch on the dough, causing the dough to tear, as well as creating a potential contamination issue. And splicing speed is always important in industrial baking operations.

The Novitool® Pun M™ Mobile Finger Punch can be used at the conveyor site and does not require electrical power. This can speed up the processing time of the splice, thus reducing conveyor downtime.

8. gauging rollers

Gauging rollers are used to gently bring the dough down to the final processing thickness. It is common to find a series of two or more gauging rollers installed on a dough processing line. The operator will utilize only the gauging rollers necessary for the dough being produced. Other gauging rollers on the line will simply be adjusted upwards so to not make contact with the dough if not needed.

ISSUES

- Dough sticks to rollers

SOLUTIONS

The FGP Food Grade Precleaner can be installed upside down on roller to release dough from the roller.

9. rotary die cutters/rotary moulding

Rotary die cutters (shown) are used to cut biscuit and crackers from a flat sheet of dough.

Rotary moulders, used for cookies and some biscuits, have a dough hopper on top that feeds dough into the concave cavities in the drum. The cookies are then released by the drum onto the conveyor belt.

ISSUES

- Dough and oils stick to conveyor belt

- Belt tracking issues

- Finger splice failure

SOLUTIONS

In the rotary moulding and rotary cutting applications a smooth low profile endless splice is required. The Novitool® Aero® Splice Press, with incorporated cool zones, is the best in the industry at creating a smooth, flat, consistent splice.

The Novitool® Pun M™ Mobile Finger Punch can be used at the conveyor site and does not require electrical power. This can speed up the processing time of the splice, thus reducing conveyor downtime.

The FGP Food Grade Precleaner can be installed against the first bend pulley after the nose roller/bar on the return side of the belt. The scraped material is often deposited into a catch pan that is emptied regularly.

All great splices begin with a perfectly squared belt end. The Laser Belt Square offers a quick and accurate way to locate a perfect belt cut reference line, every time. A square cut belt end is very important to achieving a perfect finger splice that tracks well.

The 845LD Belt Cutter offers a quick, safe, and accurate way to make a perfectly straight cut in a single pass. A straight cut is important in achieving a finger punch that is square to the belt edges

10. Scrap Reclaim Conveyors

Scrap reclaim conveyors take the lattice dough scrap and deliver it back into the pre-sheeter or divider hopper. A calculated amount of this "aged dough" is factored into the recipe of the product being produced.

ISSUES

- Dough carryback

- Belt tracking issue due to carryback

- Poor finger splice integrity

SOLUTIONS

The scraped material from an FGP Food Grade Precleaner can be removed from the belt and deposited into a catch pan that is emptied regularly.

High quality splices made quickly are key in industrial baking operations, which is why the Novitool® Aero® Splice Press is ideal for these operations. A low-profile smooth endless splice is a requirement for dough belts. This is especially true with lattice take-away belts found in cracker processing. Limited clearance between the take-away belt and the cracker dough transport belt means requires the lowest profile splice possible. The Aero® Press creates the lowest profile, flattest splice in the industry.

The Novitool® Pun M™ Mobile Finger Punch can be used at the conveyor site and does not require electrical power. This can speed up the processing time of the splice, thus reducing conveyor downtime.

11. Scrap Release/Dough Take-Away Conveyor

In the rotary die cutting process, the finished cracker/biscuit will stay on the conveyor as the remaining lattice scrap will be taken away by the lattice/scrap take away conveyor.

ISSUES

- Dough carryback

- Belt tracking issue due to carryback

- Poor finger splice integrity

SOLUTIONS

The scraped material from an FGP Food Grade Precleaner is removed from the belt and deposited into a catch pan that is emptied regularly.

High quality splices made quickly are key in industrial baking operations, which is why the Novitool® Aero® Splice Press is ideal for these operations. A low-profile smooth endless splice is a requirement for dough belts. The Aero® Press creates the lowest profile, flattest splice in the industry.

The Novitool® Pun M™ Mobile Finger Punch can be used at the conveyor site and does not require electrical power. This can speed up the processing time of the splice, thus reducing conveyor downtime.

12. Oven

Industrial baking ovens for cookies, biscuits, and crackers are long, straight ovens that can be upwards of 300 ft (91m) in length. Because cookies and crackers are deposited directly onto the baking oven conveyor belt in perfectly spaced and aligned rows necessary for the post-bake process, and are not in baking pans, the ovens are required to be in straight, long runs. The length of the oven allows for the correct time and heat necessary to bake the cookie or cracker product.

13. Cooling Spiral (shown) & Cooling Tunnels

The cooling systems for cookies/biscuits and crackers are usually done via long, covered conveyors called cooling tunnels that use room temperature air with some additional cooling fans, blowing ambient air for certain products. Sometimes the conveyors use polyester mesh belt or “filter belts” for cooling. The conveyors will consist of a deck of three conveyors, one eventually feeding onto the next until the cookies/biscuits reach the end of the third conveyor.

ISSUES

- Finger splice failure

- Belt tracking issues

- Belt scraper does not work or becomes misaligned

SOLUTIONS

When traditional plied belting is used in cooling applications an endless splice is recommended. The Novitool® Aero® Splice Press provides the best splice possible for belting used for product cooling.

The Novitool® Pun M™ Mobile Finger Punch can be used at the conveyor site and does not require electrical power. This can speed up the processing time of the splice, thus reducing conveyor downtime.

The Alligator® Spiral Lace Fastening System offers the lowest profile mechanical splice option, and is a completely non-metallic fastener. It is a great solution for pre-made replacement belts offering a hinged splice that is quick to install, keeping critical downtime to a minimum. Available in both food grade white and food grade blue options, it is a great option for all industrial baking facilities.

All great splices begin with a perfectly squared belt end. The Laser Belt Square offers a quick and accurate way to locate a perfect belt cut reference line, every time. A square cut belt end is very important to achieving a perfect finger splice that tracks well.

The 845LD Belt Cutter offers a quick, safe, and accurate way to make a perfectly straight cut in a single pass. A straight cut is important in achieving a finger punch that is square to the belt edges.

The scraped material from an FGP Food Grade Precleaner can be removed from the belt and deposited into a catch pan that is emptied regularly.

14. Cookie, Biscuit, and Cracker Shingling and Stacking Conveyors

Once the cooling process is completed, the cookies/biscuits or crackers are conveyed via a wide conveyor belt to shingling and/or stacking lanes. This positions the product in an arrangement appropriate for the packaging process.

ISSUES

- Finger splice failure

- Belt mistracking

SOLUTIONS

Shingling and stacking of cookies, biscuits, or crackers is reliant on a smooth, low profile endless splice. Splices that are taller than the belt surface or are crooked causing belt wander can create a break in the stacking or shingling process. This often requires human intervention to fix the stack or row as it continues down the conveyor. The Novitool® Aero® Splice Press creates a perfectly flat endless splice.

The Novitool® Pun M™ Mobile Finger Punch can be used at the conveyor site and does not require electrical power. This can speed up the processing time of the splice, thus reducing conveyor downtime.

All great splices begin with a perfectly squared belt end. The Laser Belt Square offers a quick and accurate way to locate a perfect belt cut reference line, every time. A square cut belt end is very important to achieving a perfect finger splice that tracks well.

The 845LD Belt Cutter offers a quick, safe, and accurate way to make a perfectly straight cut in a single pass. A straight cut is important in achieving a finger punch that is square 845 LD Belt Cutter to the belt edges.

15. Cookie, Biscuit, and Cracker Sandwiching

Sandwich style cookies/biscuits and crackers are those that have a layer of frosting or other filling in between two baked cookies/biscuits or crackers. In this process, center frosting, cheese, etc. is applied to the bottom cookie/cracker and the top cookie/cracker is then sandwiched together.

ISSUES

- Frosting/filling adheres to belt

- Belt mistracking

- Finger splice failure

- Monolithic belt failure

SOLUTIONS

The scraped material from an FGP Food Grade Precleaner can be removed from the belt and deposited into a catch pan that is emptied regularly.

All great splices begin with a perfectly squared belt end. The Laser Belt Square offers a quick and accurate way to locate a perfect belt cut reference line, every time. A square cut belt end is very important to achieving a perfect finger splice that tracks well.

The 845LD Belt Cutter offers a quick, safe, and accurate way to make a perfectly straight cut in a single pass. A straight cut is important in achieving a finger punch that is square 845 LD Belt Cutter to the belt edges.

Low profile, high quality endless splices are a requirement for sandwiching process equipment. The Novitool® Aero® Splice Press produces the lowest profile endless splice found in the industry.

The Novitool® Pun M™ Mobile Finger Punch can be used at the conveyor site and does not require electrical power. This can speed up the processing time of the splice, thus reducing conveyor downtime.

Speed of installation is key in all industrial baking applications. The Novitool® Amigo™ Splice Press speeds up the overall process of installing a new monolithic belt while simultaneously creating a superior butt joint. A clean splice with no pin holes is also an important consideration. The Amigo’s pre-heat function allows for the humidity that causes pin holes to be heated out of the joint area prior to full heat splicing. The elimination of pin holes can be a game changer as new, stricter food safety standards are adopted in the industrial baking industry.

The Novitool® Pun M™ Mobile Finger Punch can be used at the conveyor site and does not require electrical power. This can speed up the processing time of the splice, thus reducing conveyor downtime.

The Alligator® Spiral Lace Fastening System offers the lowest profile mechanical splice option and is a completely non-metallic fastener. It is a great solution for pre-made replacement belts, offering a hinged splice that is quick to install, keeping critical downtime to a minimum. Available in both food grade white and food grade blue options, it is a great option for all industrial baking facilities.

16. Metal Detector

Metal detectors are generally set up just prior to packaging after the bread product has been in contact with any metal production/processing parts. Metal detectors in industrial baking are often set up to detect a 1mm “bb” size piece of metal.

ISSUE

- Finger splice failures

Solutions

High quality splices at a consistent thickness/density are key for metal detector conveyor belts. The consistency of the splice thickness and density to that of the rest of the belt helps to eliminate false positives or other detection errors. The Novitool® Aero® Splice Press has a unique platen design that incorporates the outer cooling zones to keep the platens level with the belt surface without sinking into the belt, creating an indentation, like other presses do.

The Novitool® Pun M™ Mobile Finger Punch can be used at the conveyor site and does not require electrical power. This can speed up the processing time of the splice, thus reducing conveyor downtime.

The Alligator® Spiral Lace Fastening System offers the lowest profile mechanical splice option and is a completely non-metallic fastener. It is a great solution for pre-made replacement belts offering a hinged splice that is quick to install, keeping critical downtime to a minimum. Available in both food grade white and food grade blue options, it is a great option for all industrial baking facilities, especially those with metal detectors.

17. Product Packaging/Wrapping

In cookies/biscuits and cracker baking, the packing process may include a bagging process, a sleeving process, and a traying process, followed by a boxing process (individual boxes). For small snack size cookies/biscuits or crackers, there can be a bagging process which often includes a system to feed the bagging machine.

The boxing of bagged or packaged small cracker or cookie products is usually done very close to the bagging operation. There will be a short transport conveyor of 6'-10' (2 m-3 m), followed by the boxing operation.

There are different boxing options available:

- Horizontal Cartoners are often used to box flow wrap slugs, bags or pouches into hot-melt glued or tuck-in box sealed packages.

- Bag-in-Box systems open the pre-formed box and feed the bag into the carton from the top. They then move the carton down to be glued or sealed for completion.

Horizontal bagging is more common with standard cookies/biscuits and crackers. In this system, the baked product is stacked in chutes and then loaded into a wrap that is sealed at the ends or down the edge, creating a “sleeve” or “slug” of product. This type of packaging is called Flow Wrapping.

Issues

- Mechanical splice failure

- Finger splice failure

Solutions

High quality splices made quickly are key in industrial baking operations. When plied belting is utilized for the packaging of cookies, biscuits, and crackers endless splices are required. This is especially true with horizontal bagging equipment. A flat, seamless splice will not interfere with the horizontal bagging process. The Novitool® Aero® Splice Press makes the flattest endless splice in the industry.

The Pun M™ Mobile Finger Punch can be used at the conveyor site and does not require electrical power. This can speed up the processing time of the splice, thus reducing conveyor downtime.

The Alligator® Spiral Lace Fastening System offers the lowest profle mechanical splice option. And it is a completely non-metallic fastener. A great solution for pre-made replacement belts, offering a hinged splice that is quick to install, keeping critical downtime to a minimum. Available in both food-grade white and food-grade blue options, it is a great option for all industrial baking facilities. It is ideal for most industrial baking applications, including metal detection belts.

All great splices begin with a perfectly squared belt end. The Laser Belt Square offers a quick and accurate way to locate a perfect belt cut reference line, every time. A squarely cut belt end is very important to achieving a perfect finger splice that tracks well.

The 845LD Belt Cutter offers a quick, safe, and accurate way to make a perfectly straight cut in a single pass. A straight cut is important in achieving a finger punch that is square

to the belt edges.

18. Casing

Some packaged product will be inserted into corrugated boxboard cases. This can be done by hand or may be automated in some facilities through the use of robotic arms. The belting is most generally plastic modular and table top chain belt.

19. Shipping

Cookies and crackers are generally containerized in corrugated boxes and stacked on skids for shipping. Bread products may be placed in reusable totes for grocery chain bread supply or may be boxed for distribution through other channels to reach restaurants, institutions, schools, etc.